-

Why Do Slabs Weep?

June 2008

by Engr Ananda Ranasinghe | Photography by Zeena Marikkar

Concrete roofs, basements, exposed slabs with turfs, flower troughs and exposed terraces all form part of our contemporary building solutions. This is in addition to the wet spaces that have been an integral part of any conventional building: toilets, wash rooms, water tanks, sumps, pools and ponds.

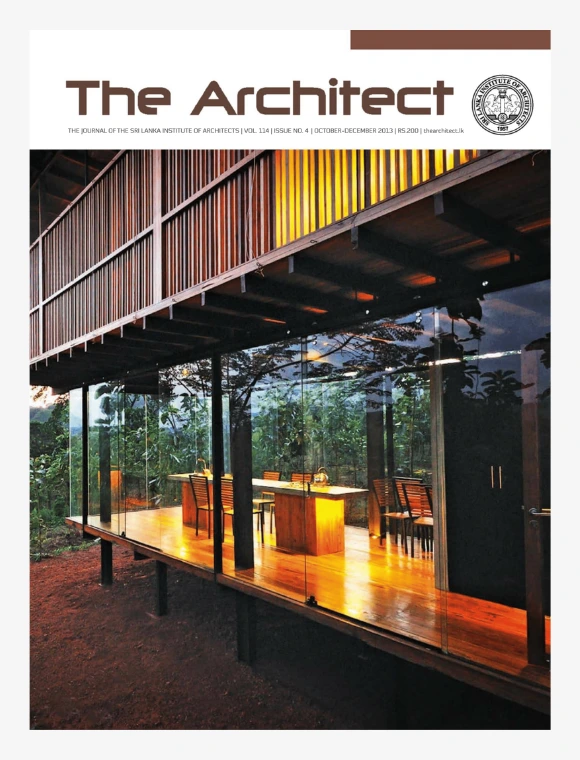

(This page & facing) Turf? Not quite. A whole concrete roof slab has been transformed into a green patch. In addition to waterproofing, proper drainage systems and growing mediums need to be in place for turfing on slabs. The weight also needs to be considered as an additional fact. (Location: Office of architects Arosha and Milroy Perera, Rajagiriya)

Wet spaces on exposed concrete surfaces are an unavoidable reality for architects and builders. The only solution is to find a practical answer to overcome the real threat of water leaks or seepage.

Waterproofing compounds available in the market are not magical mixtures to rectify probable water leaks. The secret of watertight concreting is a combination of proper structural design, good materials, and good workmanship. Although it is absolutely necessary to seek insights from a professional at the time of embarking on new construction, the following overview may serve as a general checklist for architects, clients, contractors, students, and all involved in the operations of designing and building.

At the Design desk

The water table (depth at which water is found below ground level) is an important consideration when designing basement structures and ground floor slabs. If the construction is within the water table, damp-proof membranes (usually a polyurethane sheet) will not be very effective. The concrete floor slab should be combined with the basement wall to form a ‘Tank.’

Concrete walls

Seepage through walls mainly occurs due to horizontal cracks that appear on wall surfaces. This is due to bad detailing. It is standard practice to stop steel reinforcement bars along the bottom of the wall, at the same height. This is a common area of potential crack formation, at the constant horizontal level throughout the wall. The effect can be minimised by staggering the levels at which vertical bars are stopped or lapped.

Seepage through walls mainly occurs due to horizontal cracks that appear on wall surfaces. This is due to bad detailing. It is standard practice to stop steel reinforcement bars along the bottom of the wall, at the same height. This is a common area of potential crack formation, at the constant horizontal level throughout the wall. The effect can be minimised by staggering the levels at which vertical bars are stopped or lapped.

Roof Slabs

Unlike the rest of the structure, the roof is subjected to a wide range of temperature variations. This happens during construction and throughout its lifetime. Appropriate movement joints need to be provided to accommodate the expansions and contractions, to prevent cracks. In particular, the joint between the roof slab and the walls needs careful consideration. Steel bars running at both directions of the roof slab will effectively control early thermal contraction during construction, even though the structural design for load bearing does not require it. A design which is economical in material is not always the most economical in cost and may not give the best performance over time.

At the Construction site

Water/cement ratio

Permeability of finished concrete to water increases drastically when the water/cement ratio of raw concrete increases. Tests show that permeability of fully compacted concrete with a free water/cement ratio of 0.6 is three times more than similar concrete with a ratio of 0.5. This is a clear indication that excess water in the concrete mix is harmful.

Amount of cement

Under Sri Lankan conditions, a design mixture of grade 30 concrete is preferable for exposed structures. The efficiency of grade 25 concrete may be increased in terms of resistance to water seepage by using air entraining admixtures. Although not a substitute for good design and workmanship, these may be helpful in reducing the content of water, while maintaining the workability of fresh concrete.

Joint preparation

The preparation of surfaces of construction joints to receive fresh concrete is important for watertight joints. The objective is to provide maximum bonding across the joint. This is achieved by removing the cement mortar on the surface and exposing the course aggregate.

A vertical planted wall covered with creepers. (Location: Petal Guru, Colombo 8)

Proper compaction at the time of pouring concrete is essential. Compaction is to allow better bonding of the poured concrete mix, by removing any possible air trapped within the mix. The desired degree of compaction is achieved by adhering to the usage of proper methods, machinery, and trained site staff.

Curing of concrete

This is to keep the completed concrete surface wet by pouring water regularly for a given time period. Correct curing significantly reduces drying, shrinkage, and cracking by:

• Controlling evaporation of free water from the concrete. This allows the cement in the concrete to hydrate as fully as possible during the hardening period.

• Controlling the temperature differentials in the fresh concrete.

Added Applications

These applications act in different ways. Hence, the professional has to recommend the type of waterproofing appropriate for the particular concrete works. However this is no remedy for poor design or quality of workmanship.

Water repellants

These are emulsions or solutions of siliconates. When applied to a concrete surface the treatment is absorbed into the surface and has little or no effect on the appearance.

Waterproofing membranes

Although higher in cost, these membranes can withstand thermal stresses and a range of humidity. These are brushed, sprayed, or coated on to the completed concrete surface. When dried, the coating adheres to the surface and acts as an impervious, highly reliable barrier to water.

Crystalline barriers

This technique is based on organic acids and salts of acids. When applied to a thoroughly moist concrete surface, the active ingredients react with the various concrete minerals to form soluble crystal complexes which fill out all cracks, pores, and voids, eventually going deep into the concrete structure.